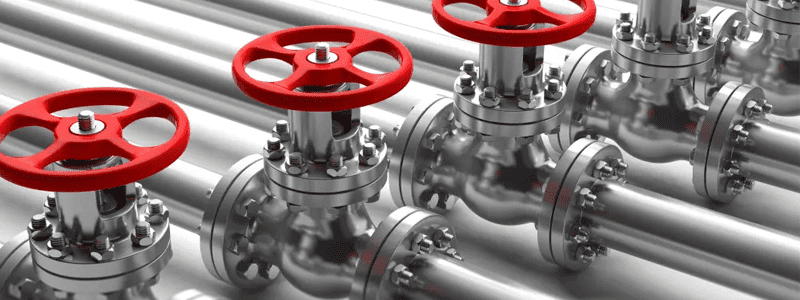

Nitium Piping is a leading Valves Manufacturer in India. We offer a wide variety of Valves in different shapes, sizes, and specifications to meet our clients' needs. Our products are recognized globally for their quality and reliability. We view our customers as partners in exporting our products.

We are a top manufacturer of Valves in India. We specialize in 2-piece and 3-piece SS ball valves, but we also have tri-clamp valves available and can make flanged ends and butt weld ends upon request. Our ball valves are made from top-quality 316 stainless steel, but we also have options in SS 304 for more affordable prices.